O-Rings

O-Rings

Downloads

Downloads

Understanding O-Rings To fully grasp the concept of O-Rings, consider these key points:

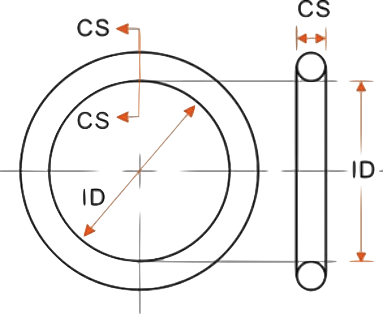

- Simple Dimensioning: The basic formula for calculating O-Ring dimensions is:

OD = ID + 2*CS

- Standardized Sizes: O-Rings adhere to various international standards, ensuring compatibility and interchangeability.

- Tolerance Matters: Maintaining precise tolerances is crucial to prevent leakage and ensure optimal performance.

- Elastomeric Nature: O-Rings are made of elastomers, materials that exhibit elasticity and can return to their original shape after deformation.

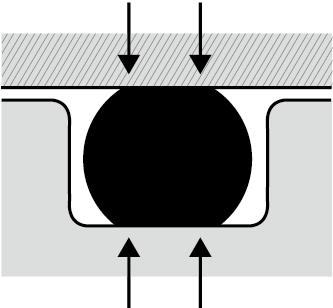

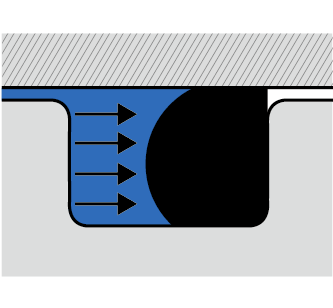

How O-Rings Seal

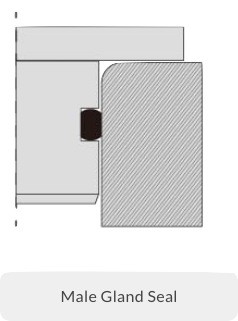

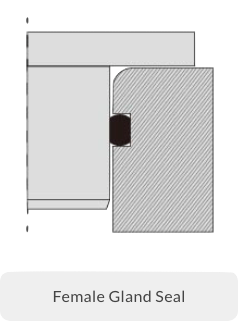

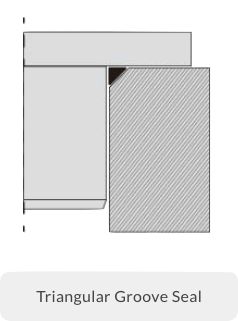

O-Ring Selection and Assembly When selecting an O-Ring for a specific application, consider four primary sealing types:

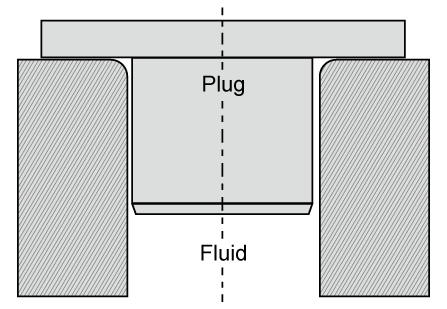

Simple application of plug and bore

- Male Gland Seal – the stem is machined to accept an O-ring, creating a radial seal at the bore

- Female Gland Seal – the bore is machined to accept an O-ring, creating a radial seal at the stem

- Face Type Seal – the face of the bore is machined to accept an O-ring, creating a seal against the plug face

- Triangular Groove Seal – a chamfer is machined at the mouth of the bore, creating a seal in the chamfer area.

The Detroit Sealing Components Advantage Quality and service are paramount. While thousands of O-Ring manufacturers exist, Detroit Sealing Components distinguishes itself by offering:

- Extensive Product Range: A wide variety of tooled, international standard O-Ring sizes, eliminating the need for tooling investment.

- Premium Elastomers: Sourcing from reputable suppliers to ensure consistent quality.

- Certified Compounds: Adherence to industry standards and specific market requirements/specifications.

- Advanced Testing: Extensive, state of the art laboratory capabilities for material development and testing.

- Diverse Hardness Options: A broad range of hardness values to suit various application characteristics.

- Precision Manufacturing: State-of-the-art tooling for accurate and reliable production.

- Surface Treatments: Optional coatings and lubricants for optimal performance and ease of assembly.

- Strict Quality Control: Rigorous quality assurance processes, including CPK/PPK analysis for critical applications.

- Comprehensive Inventory: A vast stock of standard O-Rings to minimize lead times.

Key Features

- Full range of standard O-Ring series: AS 568, BS 4518, GB/T 3452.1, JIS B2401 P/G/S/V, SMS 1586, METRIC, and JASO F404.

- Comprehensive size range: From 0.5mm (ID) × 0.4mm (CS) to 1600mm (ID) × 50mm (CS).

By choosing Detroit Sealing Components, you’re selecting a partner committed to delivering exceptional O-Ring solutions.